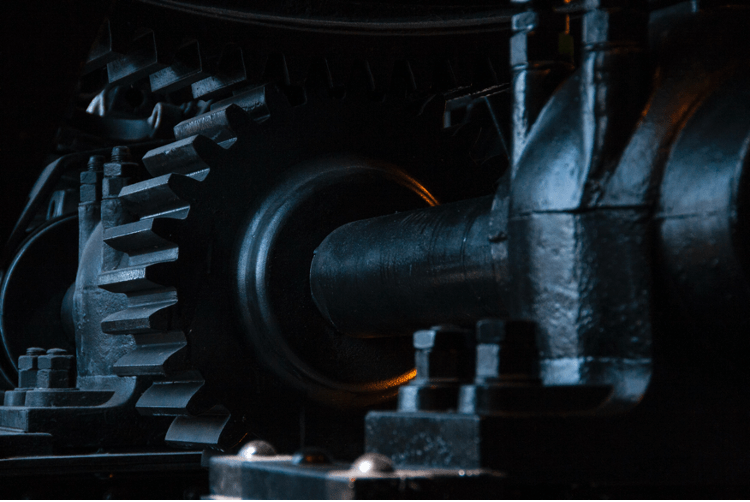

The Different Industrial Gear Cutting Machine Types and Their Uses

Gear cutting is the process of manufacturing gears.

In the past, gears were manually manufactured. However, the industrial revolution brought about a variety of new industrial gear cutting machine innovations. Today, these machines are more advanced and precise than ever before.

When choosing the right types of gear cutting machines for your business, it is imperative to take into consideration your budget, type, and quantity of gears you need to manufacture. Let’s take a look at how gears are manufactured, the five main types of gear cutting machines, and what they’re used for.

Gear Cutting Machines: How Gears Are Manufactured

Gear cutting can be done in a few ways, including:

- Broaching

- Hobbing

- Milling

- Grinding

- Shaping

Once the cutting is finalized, the gear goes through a finishing process that involves different procedures such as:

- Shaving

- Honing

- Burnishing

- Lapping

What Are the Different Types of Gears?

There are a range of gear types that can be produced using a gear cutting machine, including:

- Worm gears

- Helical gears

- Double helical gears

- Spur gears

- Bevel gears

- Herringbone gears

- Sprival bevel gears

- Planetary

The manufacturing of each gear type requires a different machine. Let’s take a closer look at each of these machine types.

5 Main Types of Gear Cutting Machines

Here are the main gear cutting machine types:

Broaching Machines

A broaching machine is a toothed tool that removes material from the gear and shapes its teeth. There are two types of broaching machines:

- Horizontal broaching machines: This type of machine is used for broaching inner splines, teeth, and other contours, but it can also be used to create forms on the outer part of the gear.

- Vertical broaching machines: This machine is used to cut the inner gear teeth. It’s mostly used in the production of larger-sized gears.

Broaching is a good option if you need to make inner gear cuttings. This method is primarily used in the heavy machinery, metal, and aerospace industries; however, it is not cost-efficient for smaller production runs.

Hobbing Machines

Hobbing machines come in all shapes and sizes since they’re used to produce both small and industrial sized gears. Some of the most widely used hobs are:

- Spline hobs

- Worm wheel hobs

- Spur hobs

- Helical hobs

- Chamfer hobs

When cutting the gear, the hob rotates and transfers the precise gear tooth shape onto the blank surface of the gear.

This method is also suitable for cutting wheels, sprockets, pinions, and splines and is rather inexpensive. It’s used in different sizes of production runs, but it’s the most efficient method for medium to high production batches.

Milling Machines

This is a type of rotary machine that moves along the gear surface while making a cut. Milling machines are mostly used in the production of spur gears and coarse-pitch gears.

There are a few types of milling machines, including:

- Horizontal mills

- Vertical mills

- Bed mills

- Jig borers

- Universal mills

- Thread mill cutters

Shaping Machines

Gear shaper machines are used to cut the teeth of both internal and external gears such as:

- Sprocket

- Spur

- Herringbone

- Bevel

The blank gear is mounted on the machine, and is cut with either pinion or rack cutters. While shaping is not as efficient as gear hobbing, it’s the preferred method to use for cutting internal teeth, especially if there are any obstructions in the vicinity of the gear.

This method is suitable for small to medium production batches.

Grinding Machines

Grinding machines are used to achieve the highest precision in the gear cutting process. The grinding wheel rotates at a very high speed and grinds the surface of the gear. These machines are usually used in the gears’ finishing process.

There are two main types of gear grinders:

- Grinding worms: These usually have a different profile than the gear and are used for continuous generation grinding.

- Grinding wheels: These are also known as profile grinders and have the same profile as the gear.

Reliable Custom Gear Cutting Services

Gear cutting can be quite costly, especially if you’re not producing gears on a regular basis or at a larger scale.

At Houston Pump and Gear, we offer cost-effective and reliable gear cutting, reverse engineering and other industrial gearbox repair services. You can even exchange gearboxes or take advantage of a complete industrial gearbox overhaul and rebuild. We offer gear cutting in Houston, as well as all over the US, Canada, and Mexico. We can assist you no matter what industry you operate in and work with a variety of gearboxes including (but not limited to) Amarillo Gearbox Repair, Lufkin Gearbox Repair, Marley Gearbox Repair, Falk Gearbox Repair, Flender Gearbox Services, and more.