In an era of rapid industrialization and technological advancements, the role of industrial gearboxes is more pivotal than ever. These sophisticated pieces of machinery form the backbone of various industries, ensuring that operations run seamlessly and efficiently.

As with any key industrial component, the importance of selecting the right supplier cannot be understated. This comprehensive guide delves deep into the world of industrial gearboxes, from the current market trends and major players in the industry to the intricate processes of assembly and disassembly.

Main Types of Gearboxes

An industrial gearbox is a closed system of gears that manage the speed, torque, and direction of a rotating system or motor. Gearboxes and their components are integral to the industrial equipment that makes the world go around. From propelling planes and wind turbines to driving production lines and cars, gearboxes keep us moving forward.

When it comes to size, gearboxes range from enormous wind turbines to micro gearboxes. Industrial gearboxes can be found across nearly all industries, including, but not limited to oil and gas, mining, food and beverage processing, power generation, trade, transportation, plastics, and metal processing. Each industry and task requires a different type of gearbox.

Helical Gearboxes

Helical gearboxes are used for many purposes but are especially effective for large, heavy-duty applications. They typically require less power than most gearboxes to operate. With the fixed angle of the helical gear teeth, these gearboxes offer consistent contact from one specific direction for an extensive period of time. This is the most common gearbox on production lines and in engines around the world, thanks in part to the enormous amount of thrust that it produces.

Worm Gearboxes

Worm gearboxes get their name from the large screw, or worm-shaped gear that they rotate on. This unique rotation allows the transmission of high torque, making it an ideal gearbox for heavy-duty tasks that require 90-degree transmissions. Because a worm gearbox cannot run in reverse, it also has a built-in braking or safety system, which is why this type of gearbox is very popular for conveyor belts. If you are looking for machinery that allows for non-perpendicular transmissions, consider the next gearbox on our list, a bevel gearbox.

Bevel Gearboxes

Bevel gearboxes can be used for many different types of power transmissions and automation applications. The gear teeth are beveled, or slanted, and the gearbox surface is cone-shaped to allow rotation between non-parallel shafts. Bevel gear teeth are either of a spiral, straight, or hypoid shape. The shape affects elements like the direction the gears move in, the amount of area that the gear contacts, and the ratio of the gears. Bevel units are commonly used in mining, food production, and more.

Planetary Gearboxes

Of the different types of automatic gearboxes, planetary units boast the newest, most advanced design within the gearbox engineering realm. The planetary gearbox is made up of three gears that orbit around a central, static gear. This allows the gearbox to effectively spread power in a more compact space than most units.

There are multiple types of planetary gearboxes, but overall, they are highly popular for applications where space and weight are more important factors than torque, for example. These types of gearboxes are some of the smallest units on the market and are known for bringing precision and durability to fields like robotics and 3D printing.

While healthy competition in the sector certainly drives progress, it also poses an important question: How can I pick a top industrial gearbox supplier I can trust?

Choosing an industrial gearbox is a complex process, requiring you to consider a variety of factors. Some of the most crucial factors for most people are the equipment’s specifications, efficiency, and durability.

To help point you in the right direction, we have assembled a list of the best gearbox suppliers. However, before we kick off the list, it will be beneficial to establish the critical factors involved in the gearbox supplier selection process.

How to Pick the Right Industrial Gearbox Supplier

A gearbox is a device, which increases and manages torque, changing the speed of gear rotation (called RPM – rotations per minute). In industrial engineering, a gearbox is the heart of the production line – it powers the motor used in manufacturing.

There are a few things that to keep in mind when making your selection of gearbox.

Let’s take a quick look at each point:

- Type of loading material and type. Most gearboxes work with a variety of different materials. However, different gearbox types are better suited for specific materials. There are six major gearbox types.

- Helical Gearbox – widely used for plastics and other materials requiring high mechanical power.

- Coaxial helical type – Also heavy-duty materials, more customized than the simpler Helical type.

- Bevel helical gearbox – Used for quarries, mining, and conveyors.

- Skew bevel helical gearbox – Has customizable teeth and gears and is used for heavy-duty materials.

- Worm reduction gearboxes – Fertilizers, chemicals, minerals (agriculture and mining).

- Planetary gearbox – Used for quick and precise gear switches in high-output tasks, and primarily used in machinery (your car has one too).

- Quality of support and warranty – Gearboxes are helpful, only for as long as they last. So, when they break, you’ll want to ensure you won’t need to pay a fortune for machine gearbox repairs. Make sure that you pick a reliable supplier with an extended warranty and dedicated customer support service.

- Efficiency & Smoothness of motion – Different gearboxes have different KPIs. Depending on your circumstances, you might want to pick a more efficient (but slower) gearbox that will preserve your hearing ability. But if you are a prominent manufacturer – you might want to choose a gearbox with higher efficiency ratings, albeit significantly louder.

- Dimensions/housing styles – Every gearbox is designed with mounting feet, connectors, and other details attached in different places. Make sure that you double-check the required dimensions for your project and check if the supplier offers customizable gearbox dimensions.

Industrial Gearbox Market Trends

By 2024, the industrial gearbox market is forecasted to hit 33.406 million USD, with a compound annual growth rate of 4.43% between 2019-2024. To what can we attribute this major increase? Industrial gearboxes are used in nearly all industries and regions around the world, and represent the technology and industrial practices of the future.

Regional Stake in Industrial Gearboxes Market Growth

It may come as no surprise, but as of 2018, over 30% of the market share of industrial gearboxes was credited to the Asia-Pacific region (China specifically), followed closely by Europe (Germany), and North America (United States). The regions of 1) the Middle East and Africa and 2) South America round out this list, but certainly should not be underestimated as major contenders in this sector. In fact, these regions are set to drive a large majority of the projected growth over the next decade due to the vast expansion of the construction industry in developing nations. Besides construction, wind power, material handling, and marine manufacturing are set to dominate the market through 2024.

Major Catalysts for Expansion

There are a number of global catalysts driving this massive market growth, but it is important to note that gearboxes are essential to the technology and manufacturing practices of the future. We couldn’t have automation in manufacturing sectors like food and beverage production, farming, robotics, and the automobile industry without durable gearboxes.

Where there’s task automation, there’s always industrial gearboxes.

Beyond automation, vast investment in renewable energy sources (mainly wind power) is also driving major industrial gearbox market trends. This capital has and will continue to encourage the development of more effective and innovative gearboxes that are transforming how we produce energy.

Leading Types of Industrial Gearboxes

Of the numerous types of industrial gearboxes, including helical, planetary, worm, spur, and bevel, planetary gearboxes are set to represent the majority of the growth through 2024. Note that planetary gearboxes are utilized in wind turbine technology, so as more companies and governments adopt wind power as a viable power source, their presence in industrial gearbox market forecasts is only set to grow.

Potential Industrial Setbacks

Potential setbacks include technical challenges like gearbox overheating, oil spills caused by faulty equipment, and common mechanical issues, like overuse of gears and long-term wear.

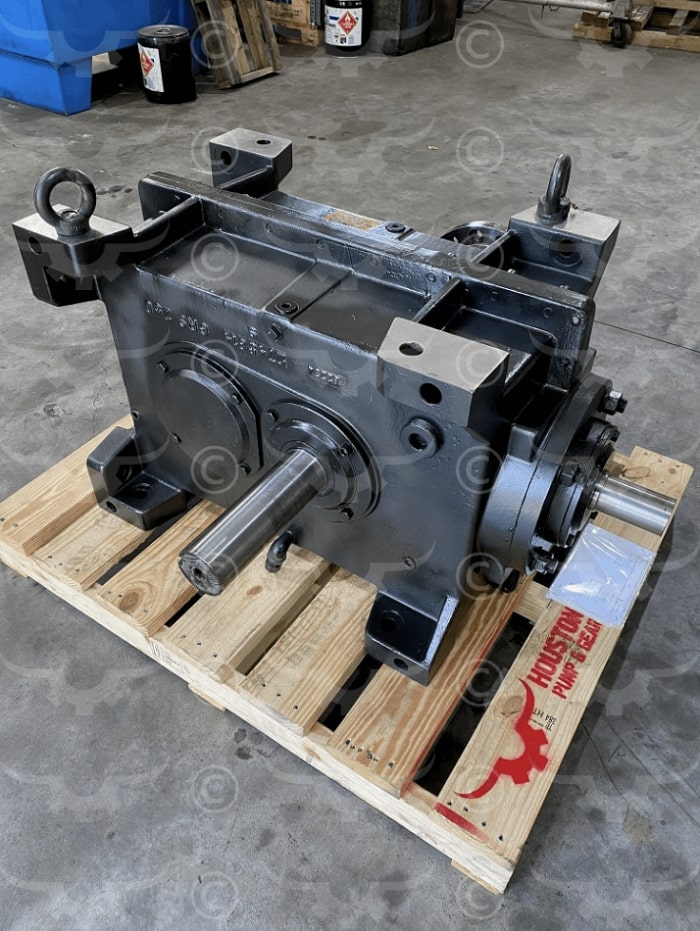

Houston Pump and Gear’s Hand in Industrial Gearbox Market Trends

While all projections point to massive growth over the next few years, one of the greatest threats to the industry is the overuse and deterioration of gearboxes and their parts. This is understandable, as a common challenge for most companies is keeping up with production when a major gearbox maintenance issue arises.

Instead of having your whole operation offline as you wait for a new part (assuming that it is available), get in touch with the gearbox repair experts at Houston Pump and Gear. We can repair your equipment quicker and more affordably than the competition. Can’t find a specific branded part, like a Western gearbox shaft or mechanical seal replacement?

We can reverse engineer one to get your production line back to work as smoothly as possible. Whatever your issue, we have an affordable and durable solution for this and other manufacturers we service, with an extensive warranty that only begins when the repair unit is back in use.

The Process of Assembly and Disassembly of Industrial Gearboxes

Having your industrial gearboxes in tip-top shape ensures higher productivity, which increases your customer satisfaction and overall profitability. But how can you increase efficiency? Comprehensive gearbox inspection and maintenance can get your equipment running faster and for longer.

The first step to extending the lifetime of your gearbox unit is breaking it down to its most fundamental state to pinpoint components that need servicing. Want a look inside the process of industrial gearbox assembly and disassembly? Read on to find out more about the industrial gearbox assembly procedure.

Before we take a look under the hood of the assembly and disassembly of industrial gearboxes, it is important to note that working with a gearbox repair specialist is key to not only executing the process efficiently but also accurately and safely.

There are many moving parts to a gearbox, so if you are working with Lightnin gearbox parts, for example, be sure to partner with a certified engineer who has experience with that specific brand. A properly assembled gearbox is key to smooth production and helps prevent serious issues for your company in the short and long term.

Now onto the nitty-gritty. Disassembling and reassembling a gearbox is one of the first steps in the gearbox repair, maintenance, restoration, or reverse engineering process. First, the unit should be taken apart and cleaned to determine the manufacturing requirements as well as the reason for failure.

So, before you or a professional touches the gearbox, it is important to find a clear area in your shop that has enough space to spread out the different parts and accessories that will be removed. To make sure that no component is lost in the process, do store all gearbox components properly as you remove them.

Taking apart or disassembling a gearbox involves removing bearings, seals, gaskets, and any other essential unit accessories. Note that each unit and brand is different, so be sure to research the proper procedure for the specific gearbox you are working on before dismantling the unit. If you don’t want to do this step manually, it is common to disassemble a gearbox using a mechanical press or puller. You should research if the presser or puller is compatible with the type of gearbox you are working with, so as not to damage the unit.

Once you have the shafts and gears spread out across your work area, it’s time to conduct a thorough inspection of the unit. An engineer will measure all of the components against their original design specifications.

Keep in mind that damaged parts will not have the same dimensions as when first installed. The specialist can then take the calculations and execute any tests or evaluations required to provide you with a detailed inspection report. This helps determine what maintenance or servicing needs to be done to get the equipment back to OEM spec.

Once the engineer has completed their inspection and all of the parts have been thoroughly cleaned, it is time to reassemble the unit, which essentially is the inverse of the disassembly process. It is important to follow the exact same, but opposite steps to ensure that the gearbox is put back together properly (again, having a trained professional on hand will help to avoid errors).

Once the unit has been fully reassembled, the gearboxes should be tested with a full industrial load to ensure that there are no issues. Then, after the unit has passed the industrial load test, the electrical components of the gearbox can be safely reassembled.

Working with a reputable service provider with experience in industrial gearbox assembly procedures, is essential to minimizing production downtime and ensuring that no components are damaged. That’s where our team of licensed engineers comes in. Here at Houston Pump and Gear, we provide durable gearbox repair services in Texas and across North America.

Top USA-Based Industrial Gearbox Suppliers

Western Gear

Western Gear has been around for almost a century. If you are looking for a reliable gearbox with a proven manufacturing record and ideal quality/price ratio – you will need to look no further.

Western Gear manufactures gearboxes of all kinds, and they can provide you with a custom device that will best suit the needs of your service. While you can find their machinery in almost every other industry, they specialize in the following:

- Aerospace

- Maritime

- Pulp and Paper

- Offshore Operations

- Metal Manufacturing

Western Gear goes by various brand lines (including Speedmaster, Seamaster, Millmaster) – but they all share the same highest quality standards.

Pro tip: Drop us a line if you are interested in Western Gearbox Servicing.

Foote-Jones

Foote-Jones has been around for over 150 years, making them one of the oldest (and most reliable) options on this list. They specialize in producing bevel helical gearboxes, and are famous for their worm gearboxes, bevel gear drives, and shafts. These units have applications in the following areas of business:

- Papermaking

- Rock crushing

- Forestry

- Mining

Regal Beloit Corporation acquired Foote-Jones to meet growing demand. Consequentially, they have an excellent economy of scale, which positively affects pricing. While their gearboxes offer excellent economy and performance, they still require some maintenance. That’s where Foote-Jones gearbox repair services come in handy.

They offer industrial gearbox for sale in the following categories:

Worm Gear

This is a standard gear arrangement in which a worm-shaped gear meshes with a worm screw. Foote-Jones offers:

- Hy-Power™ worm gear reducer

- UNI-Power™2000 helical-worm gear drive

Spiral Bevel Gear

This type of gear has helical teeth and spiral bevel bearings. Foote-Jones UNI-Power™2000 is a spiral bevel drive that has 100,000-inch lbs. output torque.

Shaft Mounted Gear

Such gears are directly installed on the input shaft with a belt and help with torque adjustment. Foote-Jones offers:

- 8000 Series™ shaft mount reducer

- PowerTorque® shaft mount reducer

Lightnin

Lightnin gearboxes differ quite a bit from other competitors on this list. Why, you might ask? Lightnin is produced by SPX Flow, a company that mainly produces machinery for the water and air purification industry. With that being said, their gearboxes are not only limited to water and air. Lightnin also works well with the following materials:

- Solvents

- Fertilizers

- Biofuels

- Food/Beverages

- Pharmaceutical

The main advantage of Lightnin is customization and expertise in the challenging waste management sector. So, if your business deals with the purification of waste materials – you should look no further. However, finding a reliable Lightnin gearbox repair company can be a challenge.

Falk (Rexnod)

Falk is the oldest household name on this list, and its history dates back to the 1800s when Henry Falk started engineering innovative couplings for wagons. Two hundred years later, Falk became one of the most reliable and well-known heavy machinery gearboxes.

Falk gearboxes were traditionally used in large machinery, including production belts, transportation, locomotives, and naval industries. Nowadays, under Rexnord management, Falk has diversified their portfolio of gearboxes to work with a variety of materials, including:

- Cement

- Plastics

- Forestry

- Mining

- Paper

Falk gearboxes are highly reliable, but if a sudden hiccup occurs – reach out to Falk gearbox repair experts in your area.

Some of the main Falk gearbox types are:

Right Angle Gear Drives

The drive shaft and output shaft in this type of gearbox are arranged at a 90-degree angle. Such gearboxes are used widely in mixing and crushing operations.

Some of the main Falk gearbox series are:

- A+ Gear Drives

- CT-Series Cooling Tower Gearbox

- Omnibox Gear Drives

Parallel Shaft Gear Drives

This gearbox type has its low and high-speed shafts in one horizontal plane, parallel to each other. These gearboxes are suitable for high torque and high-speed applications.

The main Falk Parallel shaft gearbox models are:

- Y-Unit Gear Drives

- V-Class Gear Drives

Concentric Inline Gear Drives

Concentric gearboxes have a straight-line alignment of the shafts and are used in high-torque operations.

Here are the main Falk concentric inline gearboxes:

- Planetgear Gear Reducer Drives

- UltraMax Gear Drives

- Ultramite Gear Drives

Horsburgh and Scott

This Cleveland-based company has been in the industrial gearbox business for over a century. It manufactures a wide range of gearbox types with high-quality materials. This makes their products extremely durable, and they’re one of the preferred brands in the mining, drilling, and energy industries.

Houston Gear USA Inc.

Houston Gear was established in 1975 in Stafford, Texas. The company provides premium gear equipment and high-quality customer service. Their main goals include:

- Continuous innovation

- Customer satisfaction commitment

- Quality commitment

Lufkin

Lufkin was established in 1902 in the town of Lufkin near Houston, Texas. While the company became popular as a reliable producer of pump units, it is also one of the best US gearbox manufacturers. Lufkin’s engineers produce durable equipment for the oil, gas, plastic, and rubber industries and provide top-notch customer service.

Here are some of the gearbox types it offers:

Epicyclic Gearboxes

These are also called planetary gearboxes. They have one or more outer gears that revolve around the main sun gear. Their high precision and torque-to-volume ratio make them suitable for various applications in the petrol and renewable energy industries.

Low-Speed Gearboxes

Low-speed gearboxes are suitable for a wide range of applications in the heavy-duty industry. Lufkin’s low-speed gearboxes are made with high-quality materials, have a state-of-the-art design and great durability.

Marine Gears

Marine gears help control various boat engines. Lufkin’s marine gears offer low noise and vibration levels, light and compact design, and heavy-duty capabilities.

ABB Motors and Mechanical, Inc.

This Arkansas-based company was founded in 1920. Today, ABB Motors and Mechanical produces custom gear reducers, power transmission components, and motors. In 2018 the company acquired Baldor Electric Company.

Dana Limited

Dana Limited is an Ohio-based manufacturer featured on the Fortune 500 list. The company operates in 33 countries and employs over 36,000 people. In 2021, Dana generated all-time record sales of $8.9 billion. While the company produces reliable gearbox equipment, it also has a wider range of other products for the heavy industry and automotive sectors.

Cleveland Gear Co.

Based in Cleveland, Ohio, this gearbox manufacturer produces custom-made and standard gearboxes. Their equipment is used across many industries in conveyors, generators, mills, cranes, and mixers.

Timken

Timken is an Ohio-based company with over 120 years of engineering experience. The company creates innovative gearboxes and other industrial equipment and offers reliable customer service in over 42 countries.

Curtis Machine Company, Inc.

Curtis is a Kansas-based company founded in 1946. Their 56,000 square-foot factory is dedicated to the production of gears and gearboxes, including:

- Right-angle bevel gearboxes

- Parallel shaft gearboxes

- Off-angle bevel gearboxes

- Custom-made gearboxes

Nord

Nord was founded in 1965 in Wisconsin. Today the company is a leading power transmission and gearbox manufacturer that operates in over 100 countries. The main gearbox types they offer include:

- Parallel shaft helical gearbox

- Coaxial helical gearbox

- Helical gear bevel gearbox

- Planetary gearbox

- Helical gearbox

Top Industrial Gearbox Manufacturers in World

Here are the top 10 industrial gearbox manufacturers in the world:

Flender (Germany)

Flender was founded in 1899 in Bocholt, Germany. The company is a global leader in the gearbox manufacturing industry and offers high-quality gearbox equipment for the oil, gas, and power generation industries. Flender also specializes in turbo gear production – equipment with high power transmission and minimum power losses.

Here are some of Flender’s main gearbox types:

Single Screw Extruder Gear Units

Single screw extruder units have a short delivery time, high precision, and high reliability. They’re mostly used in the plastic formation industry.

Vertical Mill Gearboxes

Vertical mill gearboxes are mainly used in raw material grinding and milling. Flender offers this gearbox type in 17 different sizes under the KMP series.

Bevel-Helical Gear Unit

Bevel-helical gearboxes have three-stage gears and can be used in different applications. Flender offers a wide portfolio of standard and custom-made bevel-helical gears.

These include units of different sizes and designs like the:

- Bevel-helical gear unit B2

- Bevel-helical gear unit B3

- Bevel-helical gear unit B4

Rossi (Italy)

Rossi is an Italy-based gear manufacturer founded in 1963. This innovative company was the first to introduce single-piece housing gear reducers and surface grinding of all gears. Rossi has an ISO 9001 certification and has established itself as a reliable and progressive gearbox provider on the global market.

David Brown (UK)

Founded in 1860 at Huddersfield, David Brown is an established gearbox manufacturer in Europe, North and South America. The company is also expanding in the Asia-Pacific market.

David Brown manufactures gears, gear units, gear cutting equipment, bearings, and shafts. Their gearbox equipment is mostly used in the oil, gas, metal, and mining industries.

Sumitomo Heavy Industries (Japan)

Headquartered in Osaka, Japan, Sumitomo produces a range of various gearboxes, including:

- Planetary gearbox

- Cycloid gearbox

- Hypoid gearbox

- Speed increasers

The company was founded in the 1930s, and since then, it was established as a reliable, high-precision gearbox equipment manufacturer.

Renold (UK)

Renold is a UK-based company established in 1864. It manufactures a wide range of high-performance gearboxes, including standard and custom-made units. The company acquired an ISO 9002 certification in 1987 and an ISO 14001 certification in 2001.

Zollern (Germany)

Zollern is a German manufacturer specializing in planetary gearbox production since 1972. In 2001 the company acquired Dorstener, which manufactures spur, planetary, and bevel gears.

Zollern is also one of the oldest family businesses in Germany and has plants in Europe, North America, and Asia. The company is known for its reliable equipment and great customer support services.

Bonfiglioli (Italy)

Bonfiglioli was established in 1956. It is the biggest reduction gearbox manufacturer in Italy, and it’s renowned for its reliable equipment on a worldwide level. The company designs and manufactures planetary gearboxes and gear reduction motors for the pharmaceutical, cement, food, beverage, oil, and gas industries.

Kumera Corporation (Finland)

Kumera specializes in marine gearbox manufacturing and is currently working on developing propulsion gearboxes. This Finland-based company offers a wide range of hybrid and custom-tailored solutions to meet all their customers’ needs. They also provide reliable after-sales service.

Sew-Eurodrive (Germany)

Sew is a big gearbox manufacturer headquartered in Bruchsal, Germany. This almost 100-year-old company has over 10,000 employees worldwide and is a well-established producer of industrial gear units, speed drives, and motors.

Rotork (UK)

This UK-based company specializes in valve gearboxes, precision control equipment, and industrial actuators for a wide range of industries. Rotork operates in 170 countries and is known for its innovative technology and reliable solutions.

Next, let’s check some of the most well-established US-based industrial gearbox manufacturers.

The Benefits of an Industrial Gearbox

Industrial gearboxes provide essential benefits to the oil and gas industry. A gearbox is used to multiply torque and reduce speeds allowing smaller motors and drives for the same application. Industrial gearboxes are designed to produce sturdy and sophisticated equipment that reduces noise, bears higher load capacity, and offers efficient and reliable output.

The most significant benefit of industrial gearboxes is the capacity to carry out various duties over a long period at very high efficiency. Due to their reliability, the market for these gearboxes continues to increase as more oil and gas industries adapt to the future of automation while increasing efficiency. Top brands like Lightnin and Western Gear have teams working on improving industrial gearboxes to keep employees safe while operating at high performance.

Different Gearbox Types In The Oil and Gas Industry

High-Speed Industrial Gearboxes

These gearboxes are key drivers of critical upstream processing applications such as pumps, compressors, and generators. High-speed gearbox applications are demanding and need high-quality design and manufacturing to provide the greatest level of reliability. Manufacturers like Philadelphia Gear produce high-speed, parallel shaft gear drives. It’s the perfect balance of engineering and long-term reliability for the oil and gas industry.

Jack Up Rig Gearboxes

Jack-up rigs are heavy-duty industrial gearboxes designed to withstand harsh conditions with a long lifespan. Successful operation of offshore rigs is dependent on effective jacking and fixation systems. Flender, a global leader in turbo gear production, specializes in creating helical turbo-parallel shaft gear units for the oil and gas industries.

Coaxial Helical Inline

These gearboxes are ideal for heavy-duty applications and are noted for their quality and efficiency. Manufacturers designed these gearboxes with a high degree of specification allowing clients to maximize load and transmission ratios. Foote-Jones Gear is a well-known brand for helical gears used in the oil and gas industries. The company has been in the industry for more than 150 years making them a leader in innovation and technology.

Pressure Pump Drives / Gear Pumps

Gear pumps can be divided into two categories: external gear pumps using two external spur gears, and internal gear pumps using external and internal spur gears. These gear pumps are very efficient in high-pressure applications like the oil and gas industry, where large amounts of water and oil need to be displaced around the clock. One of the leading manufacturers of gear pumps, Falk Gearbox, has been in the industry since the early 1900s. Since then, the brand has manufactured more than 1200 reverse reduction drives for tugboats and towboats and more than 1800 special reduction gear for marine vessels.

Trust the Experts for Industrial Gearbox Repairs

When you buy an industrial gearbox from a trusted brand you are investing in the future of your company. When a gearbox fails on a deep-sea oil rig, it can cost companies around $1.5 million per day. The downtime far outweighs the cost of purchasing a reliable industrial gearbox. That’s where Houston Pump and Gear experts come in, we specialize in machine gearbox repairs and industrial gearbox repairs for all the brands mentioned in this article.

It’s time to take control of your gearbox operations and avoid the risk of losing money during unforeseen downtime. Contact Houston Pump and Gear for a free quotation.

The realm of industrial gearboxes is vast, complex, and evolving. As we’ve navigated through its intricacies, the importance of making informed choices when it comes to suppliers and manufacturers becomes abundantly clear. With so many types of gearboxes catering to varied industries, it’s paramount to stay updated with the latest trends and insights. Moreover, the maintenance and repair of these gearboxes require expertise, underscoring the value of partnering with the best in the business.

As industries continue to evolve and expand, gearboxes will remain at the heart of many operations, ensuring that machinery functions optimally. Always trust the experts when it comes to industrial gearbox needs, and remember that the right choices today will pave the way for a smoother, more efficient tomorrow.