Mechanical seals are essential components in any pump system. They ensure the pump runs smoothly, prevent the operating liquid from leaking, and keep contaminants out of the system.

However, for optimal efficiency, you need to choose the right seal type based on your unique operating conditions and seal specs.

In this article we’ll answer the questions: “what is a mechanical seal”, “how do mechanical seals work”, and “how to select a mechanical seal for pumps”.

What is a Mechanical Seal?

Mechanical seals were created in the 1900s but didn’t become widely popular until the 1940s as a substitute for less effective mechanical packing.

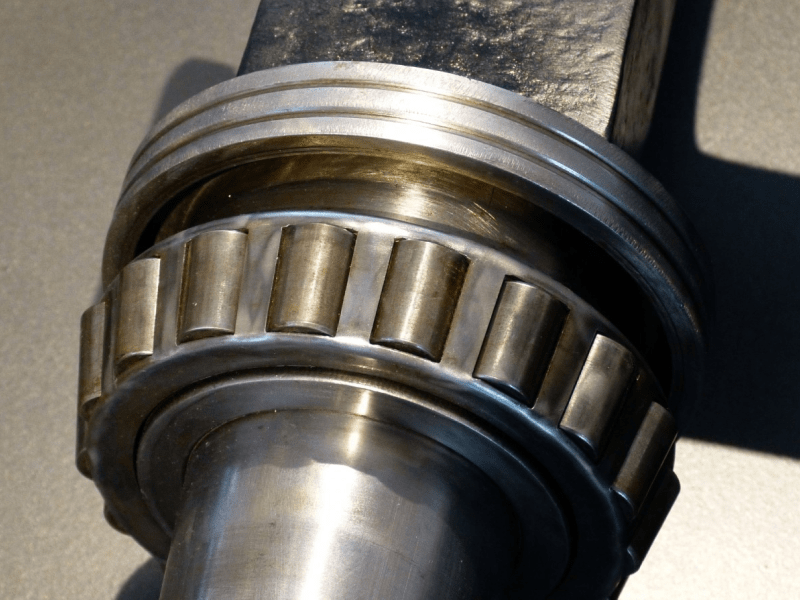

Seals have two ring seal faces which create a barrier between the pump’s static (casing) and dynamic (rotating shaft) compartments, preventing any leakage.

The seal’s main elements are:

- One ring (circulating with the rotating shaft)

- O-ring (a seal between the shaft and the ring)

- Stationary seat (a ring in the static part of the pump)

- Secondary seal (usually another O-ring)

- Spring

How do Mechanical Seals Work?

The seal’s two ring faces slide against each other, pressed together by axial forces. The mechanical seal is self-lubricating, using some of the liquid (or a special lubricating film if the liquid is abrasive) to cool and lubricate the ring faces.

Mechanical seals usually don’t require maintenance, have a simple and cost-effective design, and improve the pump’s lifespan. However, to get the maximum out of your mechanical seal, you need to ensure you choose the right seal type.

12 Types of Mechanical Seals for Pumps

Let’s look at the 12 main mechanical seal types you can choose from.

Please note: To select the right mechanical seal for your pump, there are many factors to consider. So, make sure to consult with a certified technician before you make your final decision.

O-rings

O-rings are circular gaskets that operate in both dynamic and static operations. The O-ring creates tight compression that can endure high pressure and extreme temperatures.

Gaskets

Gaskets can be used as secondary seals in static operations. They come in various shapes and sizes and can operate in extreme temperatures.

Balanced seals

In these mechanical seals, the forces on both ring faces are balanced out. This results in longer seal life and better lubrication. Balanced seals are suitable for high-pressure and high-volatility operations.

Unbalanced seals

This type of mechanical seal is more economical and less complex than balanced seals. Unbalanced seals experience less leakage but do not operate well under high pressure.

Labyrinth seals

Labyrinth seals comprise an inner and outer ring that separate low-pressure areas from high-pressure areas in rotating equipment (usually vertical pumps). Their main advantage is that they provide non-contact sealing.

Cartridge seals

Cartridge seals are usually assembled and pre-set when manufactured, allowing for easy and quick installation. This also reduces the chances of assembly error and damage. They are available in both single and double configurations.

Pusher seals

A pusher seal uses multiple springs to ensure a tight closing force. This seal type is ideal for high pressure operations. Its only disadvantage is that the elastomer beneath the seal face wears off quicker than in other seals.

Non-pusher seals

Non-pusher seals use elastomer or metal below the main seal face. They operate well in high temperatures and low to medium pressure operations.

Bellow seals

The spring element in this mechanical seal is replaced with a bellow. The seal has good endurance and can be made of metal, plastic, or elastomer.

Axial shaft seals

Axial shaft seals (or face seals) comprise a rotating and static component, an O-ring, and a spring seal. They are used as secondary seals in operations where seals are subject to heavy contamination.

Radial shaft seals

Radial shaft seals (also known as lip seals) have two main components – a cylindrical outer part attached to the casing and a sealing lip attached to the shaft. In this way, the sealing surface insulates the rotating part and prevents leakage.

Conventional seals

Conventional seals are the most basic seal type and have a lower cost. However, they are installed as individual components and require more in-depth operating knowledge.

Now that you know all the main seal types let’s look at the factors you should consider when you’re selecting a mechanical seal.

How to Select a Mechanical Seal for Pumps: 7 Factors to Consider

Here are 7 factors that can help you decide what mechanical seal you need:

Liquid

The seal material largely depends on the liquid’s characteristics. It has to be compatible with the liquid to be sealed. Otherwise, the seal might get damaged or have a much shorter lifespan (especially if you’re operating abrasive or chemical liquids.)

Pressure

The pressure levels are crucial in determining the seal materials, size, and type. A conventional seal can be sufficient in a low-pressure environment, but if pressure levels are constantly high, it’s best to invest in a high-pressure design seal.

Temperature

Determine what the operating temperature is and whether it changes drastically when the pump is off (if the liquid cools down or heats up.) This plays a crucial role in determining the seal type and materials.

Dimensions

Check the exact dimensions of your pump, including the shaft, bore, and casing dimensions, to determine what seal size you need.

Compatibility

Ensure the pump materials are compatible with the seal materials. Also, if you perform flushing often, check whether the flushing materials can damage the seal.

Shaft Speed

The shaft speed can directly affect seal materials and surface smoothness. The components will wear out much faster if they are not designed to endure it.

Seal Materials

Ensure you choose the right seal materials, especially for the parts that are in direct contact with the liquid. Some of the most durable materials are ethylene-propylene and silicon carbide.

How to Install a Mechanical Seal in a Pump

The installation process varies based on the seal type, but the general steps include:

- Before installation, ensure the shaft and sealing chambers are clean.

- Apply a thin film of lubricant where the seal will be installed.

- Install the static ring and gland first and the moving ring and spring second.

- Screw the seal evenly.

- Before fixing the gland into place, push the compensation ring for axial compression. The ring should automatically spring back.

Choose the Right Mechanical Seal Type for Your Pump

Choosing the right seal for your pump system and operation needs is crucial for maintaining maximum efficiency. However, seal selection is a complex process, requiring you to consider a variety of factors, seal types, and specs.

If you need mechanical seal consultation, do not hesitate to contact Houston Pump and Gear. We service clients from all over the US, Canada, and Mexico and provide a wide range of services, including mechanical seal repair and pump inspection in Texas.