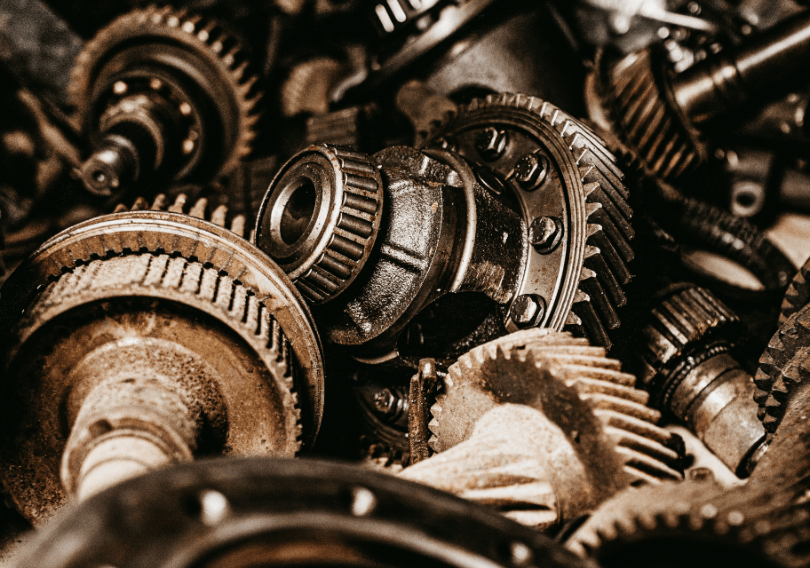

The Importance of Industrial Gearboxes

When considering ways to maximize operational efficiency and reduce costs, one of the most integral aspects to consider is the use of industrial gearboxes. Whether it be increased output, decreased costs, or a reduction of environmental footprint, the importance of industrial gearboxes and the vital advantages they provide should not be overlooked.

Increased Output

Businesses wishing to maximize production efficiency can choose well-integrated, advanced gearboxes to help speed up work. In industries such as manufacturing, food and beverage production, automotive, and agriculture, durable gearboxes are often the backbone that supports the automation of tasks, thereby increasing output and maximizing efficiency.

Cost Savings

Industrial gearboxes help companies reduce their energy costs and downtime. The efficiency and reliability they provide demonstrate the importance of industrial gearboxes, offering immediate benefits to applications as they multiply torque, match inertia, and reduce speed, thereby decreasing the overall cost of business operations.

Efficient Torque Multiplicaton

Modern gearboxes are used to increase torque while reducing the prime mover’s output shaft speed, meaning that the gearbox’s output shaft rotates at a slower rate than the input shaft. This speed reduction creates a mechanical advantage, as the gearbox multiplies the torque from the motor by an amount proportional to the gear ratio and the efficiency of the gearbox. Gearboxes such as bevel and helical models are used to increase torque in machines and reduce speed and are often used in high torque situations, such as for cement processing, for example.

Environmental benefits

In recent years, environmentally conscious manufacturing (ECM) has become an important consideration for most manufacturing organizations. With today’s global awareness of environmental risks and the pressing need to compete through efficiency, manufacturing systems adopting industrial gearboxes are evolving into a paradigm of environmental consciousness. By employing various environment-friendly strategies and techniques, businesses are becoming more eco-efficient adding to the importance of industrial gearboxes. Using industrial gearboxes is an excellent strategy to increase profits while reducing environmental footprint.

Implementing the Use of Industrial Gearboxes in Your Business

Gearboxes are progressively becoming more essential wherever power transfer is required, whether it be in automobiles, airplanes, helicopters, marine vessels, wind turbines, or any other application. The businesses taking advantage of the use of industrial gearboxes are benefiting from reduced costs, increased efficiency, torque multiplication, and reduced environmental footprints.

For gearboxes to achieve maximum efficiency and contribute the greatest benefit to your business, it is paramount that your business commit to routine gearbox inspection and maintenance. If during your maintenance you identify that your business requires gearbox repair services we would encourage you to reach out to our team of experts. You can rely on us to restore, upgrade, or reverse engineer your gearboxes, and you can rest easy knowing your refurbished equipment will last for years to come.