The Different Types of Pumps and Their Main Uses

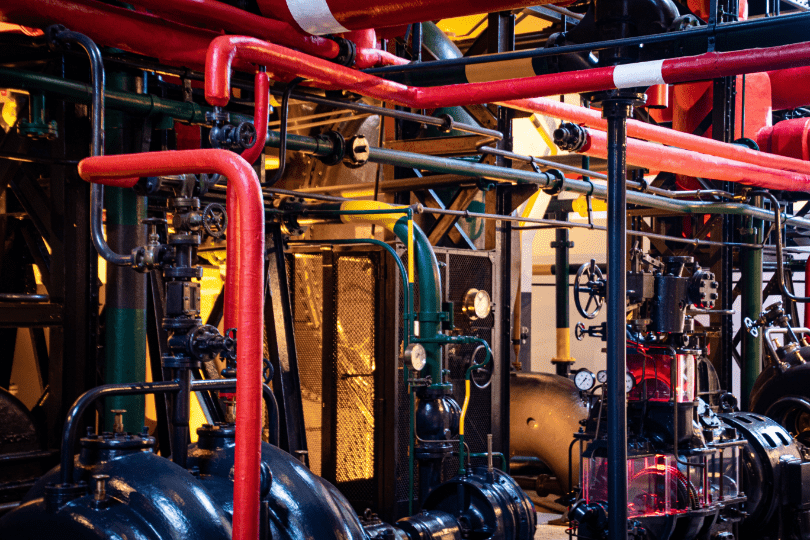

These days, there are numerous types of pumps used in a variety of industries around the world. Due to the diverse nature of these industries, every type of industrial pump offers its own benefits and applications. This article gives an overview of five industrial pump uses and which pumps are the best fit for each industry. These examples will include the two types of industrial pumps — dynamic pumps and positive displacement pumps.

Why Use Industrial Pumps for Industry Operations

The goal of an industrial pump is to move liquids either from one space to another or one level to another. This could be during the midst of sorting, excavating, transport, or other stages of production. These types of industrial pumps are most often found in the water, water treatment, chemical, oil, petroleum, and beverage industries.

The industry and application of the industrial pump will determine whether you’ll need a dynamic pump or a positive displacement pump. A dynamic pump moves liquid through its rotating impeller, creating a vacuum to help move fluid. Although a dynamic pump can displace high volumes of liquid, compared to a positive displacement pump, it generates a lower pressure with less suction and life. On the other hand, a positive displacement pump is more popular and uses pistons, plungers, and diaphragms to move liquids in a pulsing manner. These pumps can move high viscosity fluid with high pressure, which is why they are more prevalent in difficult conditions. Using the correct type of pump can eliminate the need to go through an industrial pump repair procedure as it won’t fail in harsh conditions like during oil drilling or electricity generation.

The Different Types of Pumps

Industries need industrial pumps for varying reasons, which is why you’ll find a broad range of industrial pumps. Each pump comes with its own benefits and application. Below are five of the most popular industrial pumps and their uses:

Centrifugal Pumps – dynamic

This pump is the most common type of pump as it has many different configurations available. It’s also quick to install, requires minimal maintenance, and repairs quickly. Centrifugal pumps are used in residential, commercial, industrial, and municipal applications where high flow rates and moderate head increase are required.

Reciprocating pumps – positive displacement

Reciprocating pumps are one of the most popular of the positive displacement pumps and have been around since the 15th century when they were operated manually. Over the centuries, hand-powered pumps have evolved into colossal pumping systems used in the industrial, mining, and agricultural industries worldwide. Due to the high level of force reciprocating pumps can generate, thir main function is to pump viscous liquids.

Rotary Pumps – positive displacement

Rotary pumps are used to move both fluids and gas through piping systems and include gear pumps, vane pumps, and screw pumps. These pumps create a steady and unvarying flow due to the rotating mechanisms. This is unlike reciprocating pumps, which produce a pulsing flow. Rotary pumps are most commonly used to transfer oil and other non-abrasive fluids, which is why they make up for 10% of all pumps for industry.

Submersible Pump – dynamic

As the name suggests, submersible pumps are designed to function with the pump and pump motor submerged in the fluid that needs to be pumped. The pump motor is sealed so no liquid can get into the motor and cause a fuse. Submersible pumps are also called stormwater or sewage pumps, and their applications include building services, domestic, industrial, commercial, rural, municipal, and rainwater recycling.

Gear Pump – positive displacement

Gear pumps operate with rotating motors to create a void and suction for the fluid intake. An unchanging volume of liquid moves through these gears at a constant rate if the pump speed is constant. These pumps transfer thick liquid, making them perfect for pumping grease, oils, and fuel.

In Need of Industrial Pump Repair?

At Houston Pump and Gear, we offer seal and gasket services and industrial pump repair for pumps of all shapes and sizes including the sub categories of dynamic and positive displacement pumps. Based in Houston, we offer top service with speed and efficiency and offer more than just industrial pump repair in Houston, Texas. Our clients are based as far north as Alaska, and all the way to the south in Mexico. Contact us for a free pump repair estimate!